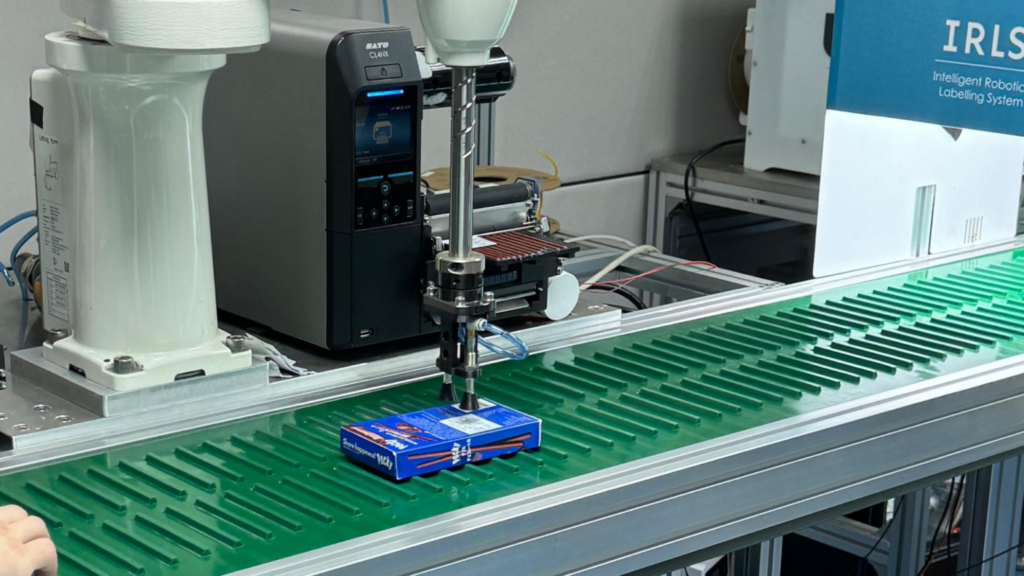

In the food processing and logistics industries, traditional manual labeling operations face challenges of labor intensity and low efficiency. Additionally, labeling errors due to operational mistakes lead to rework (reprocessing due to defects in initial production), causing significant disruption to production processes. According to existing data, robotic labeling systems can save up to 70% of manual labor while tripling production efficiency, making it an ideal technical solution to address these pain points. Below is a detailed analysis of the specific advantages of robotic labeling system in labeling dry goods, chill foods, and frozen foods from four perspectives.

Significant Improvement in Production Efficiency

Automated High-Speed Operations:

Robotic labeling systems utilize high-precision sensors and real-time image recognition technology to complete labeling quickly and accurately during continuous operations. Compared to traditional methods, the system’s labeling speed can reach three times the original rate, greatly reducing production bottlenecks caused by manual adjustments or operational delays.

Continuous Stable Operation:

The system operates without breaks and maintains consistent label position and angle for each product, particularly valuable in high-volume production environments.

Reduced Labor Costs and Rework Risks

Significant Labor Reduction:

Through automated labeling technology, businesses can reduce labor input by up to 70%, directly lowering personnel expenses. The saved resources can be reinvested in other technological innovations or production line upgrades.

Effective Rework Risk Control:

Traditional manual labeling is prone to attachment errors due to operator fatigue or environmental changes, requiring rework. The intelligent system effectively reduces such errors through automatic correction mechanisms and real-time monitoring, ensuring first-time quality for each product, saving time and costs associated with rework.

Comprehensive Improvement in Labeling Quality

Dry Goods:

For packaging with varying shapes and uneven surfaces that can cause partial misalignment or wrinkles, the intelligent system identify package contours in real-time and dynamically adjust labeling parameters to ensure labels attach in same area.

Chill Foods:

In cold storage environments, temperature and humidity fluctuations often cause labels to separate or lose adhesion. The system uses cold-resistant label materials and environmental data control to ensure long-term label stability under chill conditions.

Frozen Foods:

In freezing environments where regular adhesives often fail, causing labels to detach, the robotic labeling system combines specialized extreme cold materials and speed control technology to maintain secure labeling under extremely low temperatures, solving various technical challenges in frozen conditions.

Data Management and Complete Traceability

Complete Data Recording:

Every labeling process’s time, position, environmental parameters, and operational status are automatically recorded in the database. This makes quality inspection more convenient and enables quick tracing of specific production stages when problems occur.

Real-time Warning Mechanism:

When the system detects label attachment deviations or environmental abnormalities, it can immediately activate warning mechanisms and automatically adjust labeling parameters, reducing rework risks from minor errors and ensuring production process stability and reliability.

From the above discussion, it’s clear that intelligent labeling systems in dry goods, chill foods, and frozen foods applications not only significantly improve production efficiency but also reduce labor costs, minimize rework due to poor labeling, and achieve complete data management. This represents not just technical improvement but helps businesses achieve more stable, higher-quality products in actual production, free from the tedious problems of traditional operations. For businesses pursuing production standardization and quality control, such technological upgrades are undoubtedly a transformation worth considering.

Written by: Eric Lai / Head of Robotics

From research and development to the promotion of intelligent labelling systems, I have worked closely with clients across various industries, gaining comprehensive knowledge of product characteristics and technical details. By accurately understanding market demands, I provide businesses with efficient automated labelling solutions.

More insights of Labelling Solution:Robotic Labelling Systems: From Automation to a Data-Driven Management Tool

Success Story References: