Accelerate Product Distribution & Ensure Regulatory Compliance

Faster shelf availability across 13 Hong Kong retail locations

Our client is a prominent Japanese drugstore and beauty products supermarket chain operating 13 branches in Hong Kong. Previously, they relied on manual labor to apply Hong Kong regulatory compliance labels on imported Japanese beauty and pharmaceutical products. The time-consuming manual labeling process created bottlenecks in their warehouse operations, delaying product availability in retail stores and impacting sales performance.

Challenges

With 13 retail locations requiring a steady supply of imported products, the drugstore chain faced significant difficulties maintaining efficient warehouse operations. Manual labeling could not keep pace with the high volume and variety of beauty products, pharmaceuticals, and personal care items arriving from Japan. This created delays in getting products to store shelves, particularly problematic for items with limited shelf life such as Japanese snacks and beverages. The accumulation of unlabeled inventory in the warehouse not only constrained storage space but also increased the risk of products approaching expiration dates before reaching customers.

Solutions

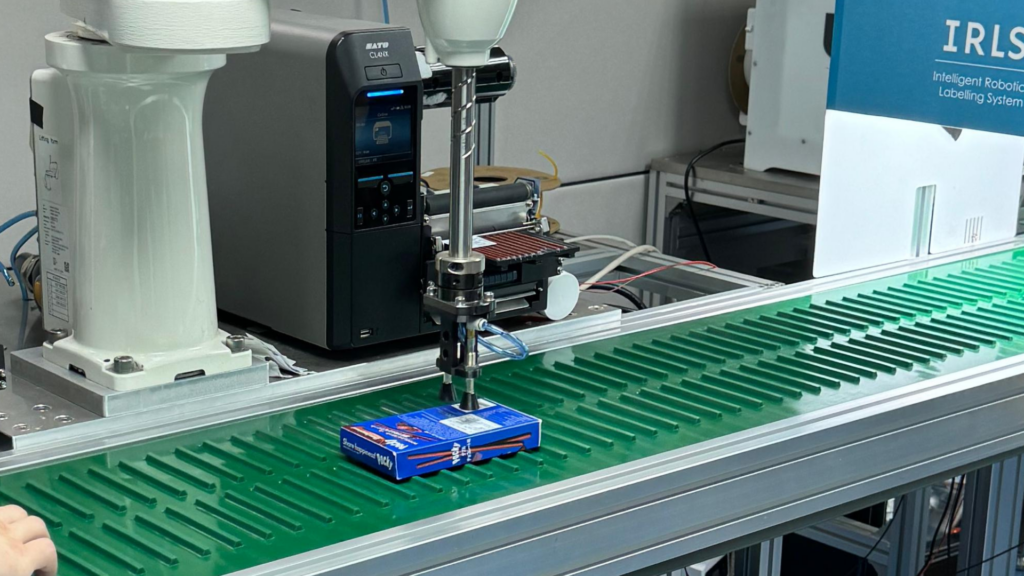

Million Tech implemented four Robotic Labeling Systems in the client’s warehouse facility to handle the high-volume labeling requirements of imported Japanese products. These automated systems can process multiple product SKUs simultaneously while ensuring accurate application of Hong Kong regulatory compliance labels. The solution operates with minimal manual supervision, dramatically reducing the labor-intensive nature of the previous process. The robotic systems work continuously to maintain consistent throughput, ensuring products move quickly from receiving to distribution across the 13 retail locations.

Values created

The Robotic Labeling Systems delivered substantial operational improvements for the drugstore chain. Manpower requirements were reduced by 70%, freeing staff resources for other value-added activities while significantly lowering labor costs. The accelerated labeling process ensures products reach store shelves faster, improving inventory turnover and customer satisfaction.

To Read More Success Stories about Robotics Labelling System