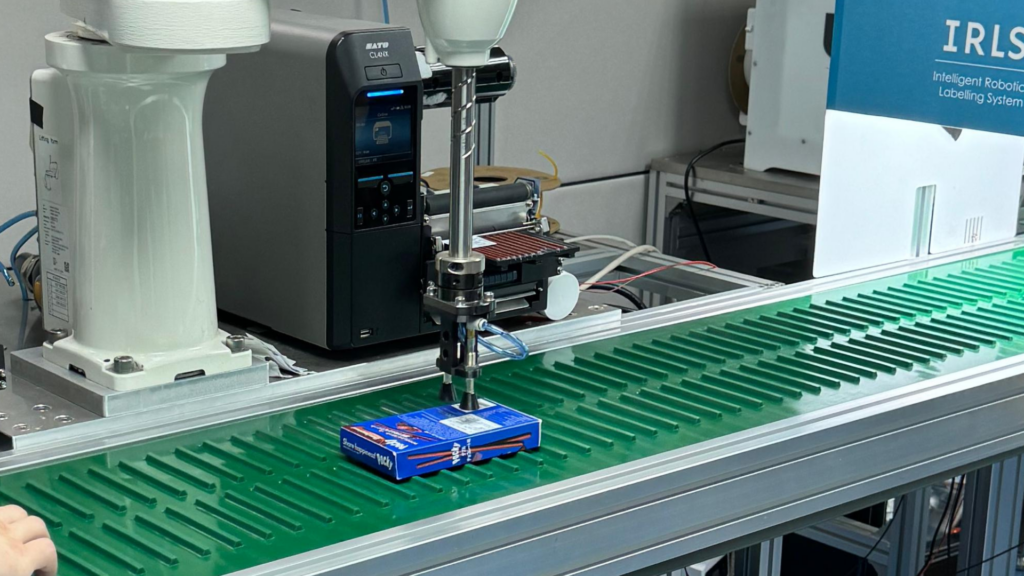

As manufacturing enters the Industry 4.0 era, labelling is no longer just a small step in the production process but a vital element that provides rich data for businesses. Especially with the implementation of Robotic Labelling Systems, labelling has evolved from a simple operational task to a powerful platform for data management and analysis, enabling businesses to gain deeper insights into production and market demands.

When a robotic labelling system is integrated with a backend management system, it not only improves production efficiency but also empowers businesses to make more precise and informed operational decisions through data. Below, we’ll explore how robotic labelling systems help management gain full control over labelling data and deliver greater value to enterprises.

The Data-Driven Capabilities of Robotic Labelling Systems

Robotic labelling systems are more than just tools for applying labels. They offer robust backend data management capabilities, helping businesses visualize production data and transform it into actionable business insights. Here are the core functionalities provided by these systems:

1. Real-Time Monitoring of Daily Labelling Volume

- The system records the total number of labels applied daily, including data by shifts or specific timeframes.

- Management can easily monitor daily production progress, ensuring labelling operations are synchronized with the overall production line.

2. SKU-Level Labelling Data

- The system tracks the number of labels applied to each SKU (Stock Keeping Unit) and the types of labels required.

- Businesses can analyze which products have the highest shipment volumes and identify those with fluctuating demand.

3. Monthly Data Comparisons and Trend Analysis

- The system automatically generates monthly labelling reports, showing trends in daily labelling volumes and ranking SKUs by the number of labels applied.

- Management can easily compare data across months, quickly identifying fluctuations in production efficiency and forecasting seasonal demand.

4. Demand Forecasting and Production Planning

- By analyzing labelling data for each SKU, the system helps businesses predict which products will experience higher demand, enabling them to adjust production plans and allocate resources accordingly.

- It also identifies products with the fastest-growing shipment volumes, providing valuable insights for market strategies.

Key Benefits for Management: Data Visualization and Decision Support

The backend platform of robotic labelling systems is designed to help management easily access valuable data and make faster, more informed decisions. Here are the main benefits that these systems bring to enterprise management:

1. Clear Data Visualization for Quick Insights

- The system provides an intuitive dashboard displaying daily, weekly, and monthly labelling data.

- Management can view key metrics such as total daily labelling volume, SKU-specific labelling data, and label inventory status on a single platform, making complex production data simple and actionable.

2. Improved Production Transparency and Reduced Risks

- Real-time data enables management to quickly identify issues, such as a sudden drop in labelling volume for a specific SKU, potentially signaling reduced demand or production errors.

- Data transparency also fosters better collaboration across teams, ensuring that every part of the production line operates smoothly.

3. Market Demand Prediction and Business Planning

- By analyzing labelling data for different SKUs, management can track changing market demands and proactively plan inventory and production to avoid overproduction or shortages.

- Additionally, the system can help businesses identify high-demand products, allowing for better resource allocation and increased profitability.

4. Historical Data for Long-Term Optimization

- With access to comprehensive historical data, businesses can analyze long-term labelling efficiency trends and uncover opportunities for improvement, such as identifying which shifts are the most efficient or which production processes could be further optimized.

Practical Applications: Leveraging Labelling Data to Boost Competitiveness

1. Demand Forecasting in the Food Industry

The food industry often experiences fluctuating labelling demands, especially during holidays or promotional periods. By analyzing SKU-specific labelling data from robotic systems, businesses can predict which products will see high demand in specific periods and adjust production plans accordingly, avoiding stock shortages or overproduction.

2. Compliance Management in the Pharmaceutical Industry

The pharmaceutical industry has strict regulatory requirements for labelling accuracy. Robotic labelling systems not only ensure precise labelling but also keep detailed records of labelling data for each batch, supporting full traceability and meeting compliance standards.

3. Market Insights for the Electronics Industry

Demand for electronic products often shifts with market trends. By leveraging SKU-level labelling data, businesses can quickly identify which products are gaining market traction, optimizing resource allocation and focusing efforts on high-demand products to maximize sales.

Driving a Data-Driven Future with Robotic Labelling Systems

In the era of Industry 4.0, robotic labelling systems are no longer just about automating manual tasks. They enable businesses to unlock the power of data, providing insights into both production and market demands to support more precise decision-making.

When a labelling system is integrated with a robust backend data platform, management gains the ability to monitor daily labelling operations, analyze product demand trends, and even predict future market behaviors. This level of data-driven precision is becoming an essential factor for enterprises to stay competitive and succeed in today’s fast-changing environment.

Written by: Eric Lai / Head of Robotics

From research and development to the promotion of intelligent labelling systems, I have worked closely with clients across various industries, gaining comprehensive knowledge of product characteristics and technical details. By accurately understanding market demands, I provide businesses with efficient automated labelling solutions.

More insights of Labelling Solution:提升標籤效率:智能機械臂的角色

Success Story References: